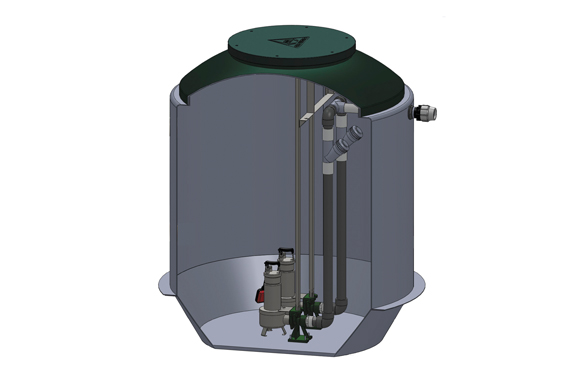

For pumping sewage and water to mains.

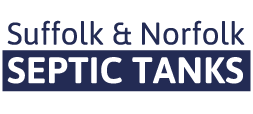

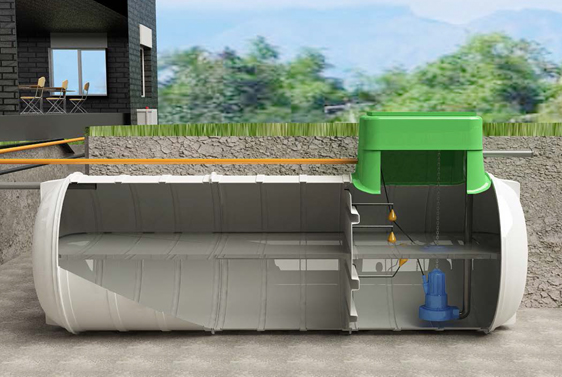

When discharge to mains is required, but to do so by gravity is impractical, a pump chamber system will be needed.

Although available as floor-mounted units for indoor applications such as basements, the vast majority are installed outdoors at levels to suit on-site conditions and topography.

- Where foul water drainage from a domestic property is to be pumped to the mains the effluent receiving chamber should be sized to contain 24-hour inflow to allow for disruption in service, the minimum daily discharge being taken as 150 litres per person per day.

- For other building types the capacity of the receiving chamber should be based on the calculated daily demand of the water intake for the building or when only a proportion of the foul sewage is to be pumped then the capacity should be based pro–rata.

- If the sewer is to be ‘adopted’ by a local water authority, please contact Marsh Industries as Sewers for Adoption (SFA) specification and additional local authority related criteria may apply.